Connet high quality cladding power stripper has unique optical properties. This device can absorb the light transmitted in the inner cladding of the double-clad fiber. In double-clad fiber, all the light transmitted in the optical waveguide formed by the inner cladding with large numerical aperture (>/=0.46) and the fiber core with the small numerical aperture (up to 0.06) can be ‘absorbed’ by the cladding power stripper and meanwhile the signal light transmitted in the fiber core can be well maintained including the signal light power and the beam quality factor (M2).

The high quality cladding power stripper of Connet is the ideal device for the double-clad fiber laser/fiber amplifier to remove the residual pump light in the cladding, the ASE light leaking from the fiber core into the inner cladding and the higher-order mode signal light. This document only shows the specifications of the standard cladding power strippers. Connet also can customize the products with different fiber types according to customers’ requirements. If you have specific requirements, please contact Connet sales staff.

Features:

• Bear high power

• High power absorption

• Minimum signal power loss

• Meet RoHS standards

Applications:

• High power fiber laser

• MOPA-structure high power fiber amplifier

• Multistage double-clad fiber amplifier

• Other scientific research

Main Test Equipment:

|

Test Equipment |

Equipment Model/Parameter |

|

Multimode Pump Laser Diode |

915nm 65W, Output Fiber: Nufern MM-S105/125-22A |

|

7*1 Pump Combiner |

Input Pump Fiber: Nufern MM-S105/125-22A Output Signal Fiber: Nufern LMA-GDF-20/400-M |

|

Power Meter |

Ophir F150A |

|

Thermodetector |

FLIR E40 |

|

Water-cooling Plate |

Internally integrate the cooling water channel with the set water temperature of 20℃. |

|

CPS |

Fiber type: Nufern LMA-GDF-20/400-M |

Test Method:

Test Results:

| Output Power from Combiner (W) |

50 |

100 |

150 |

200 |

| Output Power from CPS (W) |

0.95 |

1.80 |

2.65 |

3.55 |

| CPS Stripping Efficiency (%) |

98.1 |

98.2 |

98.2 |

98.2 |

| CPS Cold Surface Temperature (℃) |

20 |

20 |

20 |

20 |

| CPS Max. Temperature (℃) |

27.3 |

34.9 |

42.1 |

50.3 |

| CPS Max. Temperature Rise Coefficient (℃/W) |

0.146 |

0.149 |

0.147 |

0.151 |

| Temperature Distribution Figure |

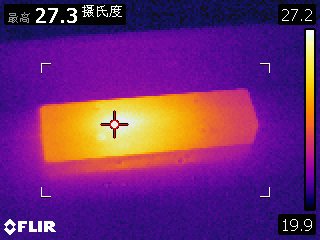

Fig. 1 |

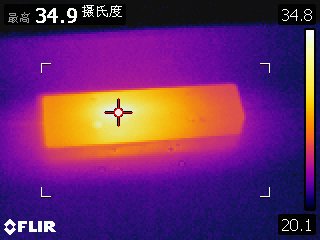

Fig. 2 |

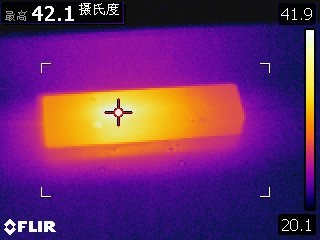

Fig. 3 |

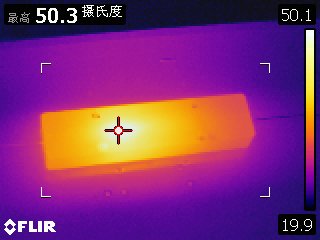

Fig. 4 |

Fig. 1 CPS Temperature Distribution @ Input 50W Pump Light Fig. 2 CPS Temperature Distribution @ Input 100W Pump Light

Fig. 3 CPS Temperature Distribution @ Input 150W Pump Light Fig. 4 CPS Temperature Distribution @ Input 200W Pump Light

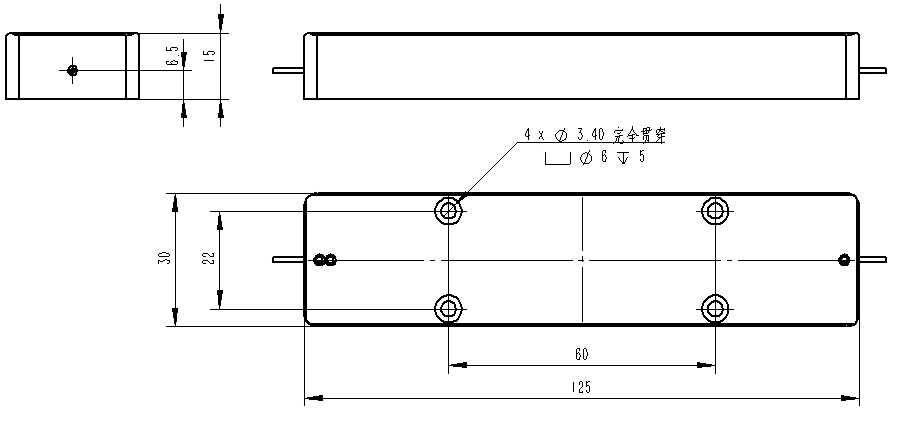

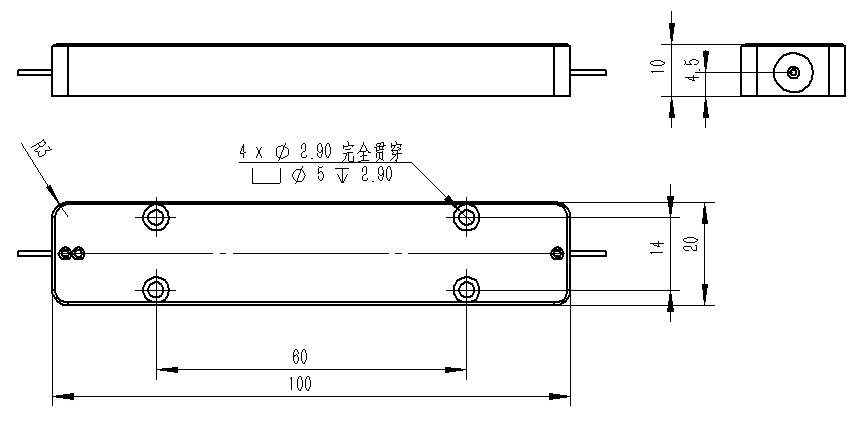

Mechanical Design and Mounting Dimension (Unit: mm):

Fig. 5 High Power CPS (Max. Stripping Power: 200W)

Fig. 6 High Power CPS (Max. Stripping Power: 50W)

Instructions:

• The cladding power stripper is incapable of storing higher power. Please Install it on an actively cooled cooling plate and fill the gap between the stripper and the cooling plate with the thermally conductive material to reduce thermal resistance.

• The cladding power stripper has a certain directionality. Please use it in the direction marked in the product label.

• The fiber inside the cladding power stripper is specially treated. Please do not touch it.